Hyundai Motor Group pushes human-robot collaboration roadmap, Atlas to start factory work from 2028

KUALA LUMPUR: Hyundai Motor Group has used CES 2026 to spell out a broader AI robotics strategy it says is aimed at getting robots working alongside people in real workplaces, starting with factories.

The Group’s CES theme this year is “Partnering Human Progress”, and the pitch is less about a single gadget and more about an ecosystem, training, manufacturing scale, and partnerships that can move humanoid robots from demo stages into daily use.

Photo from Hyundai

Photo from HyundaiAlso Read: Hyundai Motor Malaysia, EON team up again, new Klang Valley and Penang outlets due H1 2026

A key part of the plan revolves around Boston Dynamics, which Hyundai acquired a controlling stake in back in 2021. Hyundai says it has already been deploying Boston Dynamics robots in industrial settings, and CES 2026 is where it is drawing a clearer line between that early usage and a roadmap toward wider adoption.

Hyundai frames its next phase around what it calls Physical AI, meaning AI that is tied to hardware operating in real-world environments, collecting data, learning from it, and making autonomous decisions. In its description, that covers areas like robotics, smart factories, and autonomous driving.

Three partnership lanes

Hyundai Motor Group says its strategy is built on three “foundational partnerships”:

-

Humans and co-working robots, with robots taking on hazardous, repetitive, or physically demanding tasks, beginning in manufacturing.

-

Hyundai’s Group Value Network paired with Boston Dynamics, combining robotics R&D with Hyundai’s global production footprint to create an end-to-end AI robotics value chain and safe training grounds.

-

Partnerships with AI leaders, bringing in external expertise to accelerate next-generation humanoid development and support safer deployment.

Photo from Hyundai

Photo from HyundaiAtlas is the headline, production use targeted from 2028

Boston Dynamics unveiled the product version of its new Atlas humanoid at CES 2026, positioned as an industrial robot designed to work inside existing facilities. Hyundai says Atlas will be introduced at Hyundai Motor Group Metaplant America (HMGMA) in Savannah, Georgia, with a phased rollout starting with parts sequencing from 2028, then expanding to component assembly by 2030.

Hyundai’s reasoning is straightforward, validate safety and quality benefits process-by-process, then scale. The company also says the goal is to reduce physical burden on workers by having robots take higher-risk tasks, while humans handle oversight and training.

Hyundai highlights Atlas hardware capability claims such as 56 degrees of freedom, tactile-sensing hands, a 110 lbs (50 kg) lifting ability, water resistance for washdowns, and operation between -4 and 104 degrees Fahrenheit (20°C to 40° Celsius). It also claims most tasks can be taught in under a day, and that Atlas is designed for autonomous operation including automatic battery replacement.

Building the training and factory backbone

To support the robotics push, Hyundai outlines a set of factory and training systems. It points to its Software-Defined Factory (SDF) approach, first shown at Hyundai Motor Group Innovation Center Singapore (HMGICS) and expanded at HMGMA, using production data to improve robot learning and performance.

It also mentions the Robot Metaplant Application Center (RMAC), described as a training “engine” where robot movements and real-world operational data are used for continuous retraining. RMAC is set to open in 2026 in the U.S., with RMAC-trained Atlas units planned for sequencing tasks by 2028 and more complex assembly work later.

Hyundai also references a strengthened partnership with NVIDIA, saying it plans to use NVIDIA’s AI infrastructure and simulation frameworks to accelerate Physical AI development.

DeepMind tie-up and two key quotes

On the AI side, Boston Dynamics announced a strategic partnership with Google DeepMind to accelerate next-generation humanoids and scale deployment “safely and efficiently.”

“The convergence of robotics and AI represents more than a technological advancement. It is a transformative innovation that will make human life safer and more enriching. By combining capabilities of Boston Dynamics and Google DeepMind through this strategic partnership, we are taking a significant step toward redefining the future paradigm of the industry.” – Zachary Jackowski, Vice President and General Manager of Atlas at Boston Dynamics.

“We are excited to begin working with the Boston Dynamics team to explore what’s possible with their new Atlas robot as we develop new models to expand the impact of robotics, and to scale robots safely and efficiently.” – Carolina Parada, Senior Director of Robotics at Google DeepMind.

RaaS, production scale, and CES booth lineup

Hyundai also reiterates its interest in Robotics-as-a-Service (RaaS), including support like OTA updates, maintenance, and remote monitoring, and says it is targeting an annual manufacturing capacity of 30,000 robot units by 2028.

At CES 2026, Hyundai says it is showcasing Atlas alongside Boston Dynamics Spot and Stretch, plus other robotics projects including MobED, an Automatic Charging Robot, and additional autonomous and collaborative robots across its wider group portfolio.

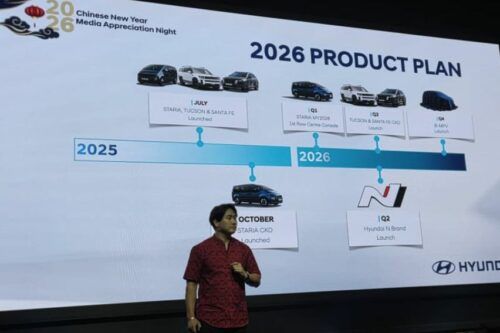

Also Read: Hyundai STARIA now locally assembled in Malaysia, priced from RM179,888

-

Explore Hyundai Staria

Hyundai Staria Related Stories

- News

- Featured Stories

Hyundai Car Models

Don't Miss

Malaysia Autoshow

Trending & Fresh Updates

- Latest

- Popular

You might also be interested in

- News

- Featured Stories

Hyundai Featured Cars

- Popular

Compare & Recommended

|

|

|

|

|

|

Seating Capacity

10

|

7

|

7

|

8

|

11

|

|

Fuel Type

Diesel

|

Petrol

|

Petrol

|

Petrol

|

Diesel

|

|

Engine

2199

|

1997

|

1598

|

1998

|

2151

|

|

Power

175

|

148

|

165

|

137

|

199

|

|

Torque

430 Nm

|

200 Nm

|

240 Nm

|

183 Nm

|

440 Nm

|

|

Transmission Type

Automatic

|

CVT

|

Automatic

|

Automatic

|

Automatic

|

|

Ground Clearance

-

|

-

|

-

|

200 mm

|

172 mm

|

|

|

Trending MPV

- Latest

- Upcoming

- Popular