Proton R&D centre in China turns one; marks key role in new model development

- KEY TAKEAWAYS

- How is PRDC driving innovation in Proton's R&D and EV development?

- Structured approach to product development

- Advancing electrical & electronics (E&E) integration

- Chassis, NVH & fuel efficiency improvements

- First EV milestone – e.MAS 7

- Thermal, charging & regenerative tech validation

- Future plans: Expanding R&D & workforce

KUALA LUMPUR: In April last year, Proton established a Research and development centre (PRDC) in China as part of its joint efforts with business partner Geely. Located within the Geely Automobile Research Institute at Hangzhou Bay, this new facility is now celebrating its first anniversary.

KEY TAKEAWAYS

Where is the Proton’s R&D centre located in China?

Proton’s R&D centre in China is located within the Geely Automobile Research Institute in Hangzhou Bay.How did Geely support the development of Proton e.MAS 7?

Geely provided access to advanced facilities including battery laboratories, smart vehicle development centres, and powertrain test benches at Hangzhou Bay.Within a year, the venture empowered the brand’s R&D capabilities and accelerated its technological advancements, benefiting all Proton models.

Photo from Proton

Photo from ProtonHow is PRDC driving innovation in Proton's R&D and EV development?

Structured approach to product development

Ensuring alignment and efficient progress is a well-structured New Product Development System that comprises everything from product strategy to final validation and supports integration across teams.

Advancing electrical & electronics (E&E) integration

The collaboration also helps in integrating advanced vehicle E&E technologies for Proton’s next-gen models by providing access to cutting-edge platforms and tools.

Wan Fatin Nur Amira Binti Wan Rusli, Senior Engineer at the centre looking after Electrical and Electronics (E&E) and integration work started, “Over the past three months, I have seen how PRDC is contributing to the development of PROTON’s next-generation of intelligent vehicles through the integration of advanced vehicle E&E technologies.”

Chassis, NVH & fuel efficiency improvements

The facility also undertakes chassis and suspension optimisation tasks to offer Malaysian drivers refined driving dynamics. It aims to reduce NVH levels and improve fuel and braking efficiency.

Photo from Proton

Photo from ProtonFirst EV milestone – e.MAS 7

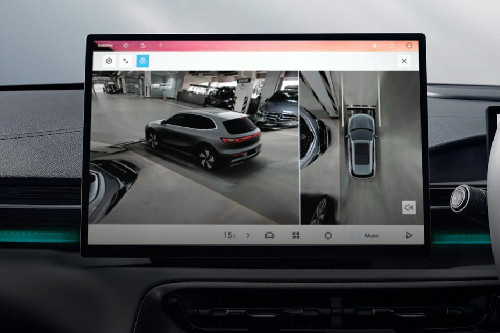

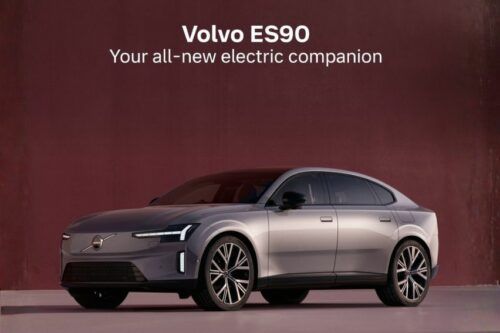

The most notable result of the venture is Proton’s first-ever electric car, the e.MAS 7. Geely facilitated the development of the EV by providing battery labs, smart vehicle centres, and powertrain test benches in Hangzhou Bay.

The e.MAS 7 has been winning the customers’ hearts with its strong performance, spacious cabin, advanced features, and value-for-money proposition. It now holds a 26% market share in the Malaysian EV market.

Photo from Proton

Photo from ProtonThermal, charging & regenerative tech validation

Over the past year, Proton engineers also worked in engineering coordination, timeline execution, and cross-functional collaboration and achieved key milestones in validating thermal management, charging efficiency, and regenerative braking. It enhances safety, durability, and range, which are crucial for Malaysia’s tropical climate.

“Through these efforts, we are on track to introduce a reliable, high-value EV tailored to ASEAN consumers,” Omar Farhan Bin Omar, Senior Engineer said.

Zulkifli Bin Fadzlullah, Senior Engineer in Testing & Development, added, “We are in daily contact with PROTON R&D Malaysia, sharing technical knowledge and testing data that will help improve testing capabilities in Malaysia. This ensures Proton can develop more competitive and high-quality vehicles in the future.”

Photo from Adam Aubrey

Photo from Adam AubreyFuture plans: Expanding R&D & workforce

Looking ahead, Proton aims to double the workforce at the R&D centre by the end of this year to support new product development and technical capacity. It seeks to strengthen independent innovation in Malaysia, especially in E&E architecture, EV development and exchange programs, and real-world testing programs to enhance local engineering capabilities.

Mohd Haizam Bin Ghazali, Head of R&D in Engineering & Technical, said, “This collaboration serves as a crucial bridge to PROTON’s product development capabilities by providing engineers access to advanced facilities and empowering them without shifting core R&D operations away from Malaysia. We're planning to double our workforce by the end of the year as part of our expansion efforts, which will significantly boost our R&D capabilities as a group. Moving forward, we can expect to see more technological advancements integrated into our latest models, reflecting our commitment to innovation and progress for both PROTON and Malaysia.”

Also read: Proton ties up with Continental to offer tyre replacement, targeting 60 outlets by Dec 2025

-

Explore Proton e.MAS 7

Proton e.MAS 7 Related Stories

- News

- Featured Stories

Proton Car Models

Don't Miss

Malaysia Autoshow

Trending & Fresh Updates

- Latest

- Popular

You might also be interested in

- News

- Featured Stories

Proton Featured Cars

- Latest

- Upcoming

- Popular

Latest Proton e.MAS 7 Car Videos on Zigwheels

Compare & Recommended

|

|

|

|

|

|

Seating Capacity

5

|

7

|

5

|

5

|

5

|

|

Fuel Type

Electric

|

Petrol

|

Petrol

|

Petrol

|

Petrol

|

|

Power

215

|

104

|

110

|

147

|

194

|

|

Torque

320 Nm

|

136 Nm

|

205 Nm

|

180 Nm

|

290 Nm

|

|

Transmission Type

Automatic

|

Automatic

|

Automatic

|

CVT

|

Dual Clutch

|

|

Ground Clearance

-

|

220 mm

|

-

|

-

|

-

|

|

Engine

-

|

1496

|

1199

|

1999

|

1598

|

|

|

Trending SUV

- Latest

- Upcoming

- Popular